THF Dehydration

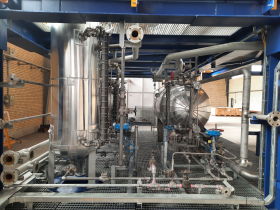

Dehydration is one of most important process placed at upstream side for most of Gas Treatment Units, Oil Refineries, Natural Gas Plants and Petrochemical Facilities. This unit require effective Dehydration Package as part of their process. Dehydration system is a setup used Special Adsorbents to eliminate Water (Moisture), from Process Stream. Water is the most common contaminant in feed streams, and is a source for not only hydrates, but corrosion and erosion problems.

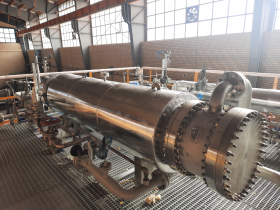

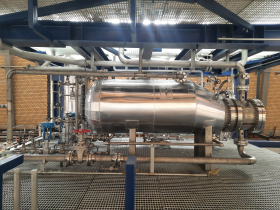

Although the normal Dehydration Packages and its Adsorbent is familiar and common for most of the process, however for some special cases (e.g., THF Dehydration) due to special nature of Process Fluid, a very specific Adsorbent should be supplied to resist structurally against process fluid’s molecular attack.

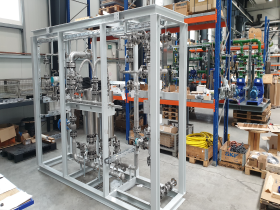

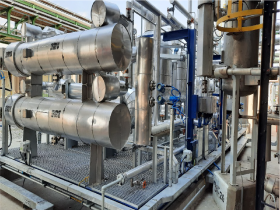

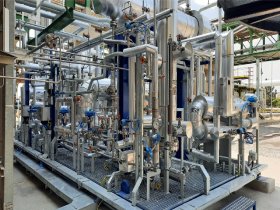

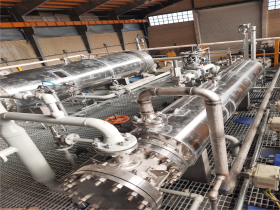

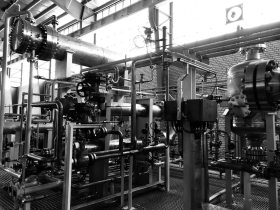

THF (Tetrahydrofuran) is a flammable heterocyclic compound, which is used in SHAZAND Petrochemical Company processes for different purposes. Client intended to have a Dehydration system to removing water content of Liquid THF from 400 ppmW to less than 10 ppmW.

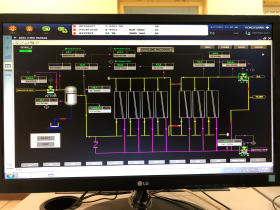

SINA has designed Adsorbent Column and supplied most compatible substance for this purpose, which has been an excellent choice to outperform in THF dehydration Process.

Process successfully run at Client site and its Performance Test has been successful.