Contract Duration: 15 Months

Date of operation: November, 2018

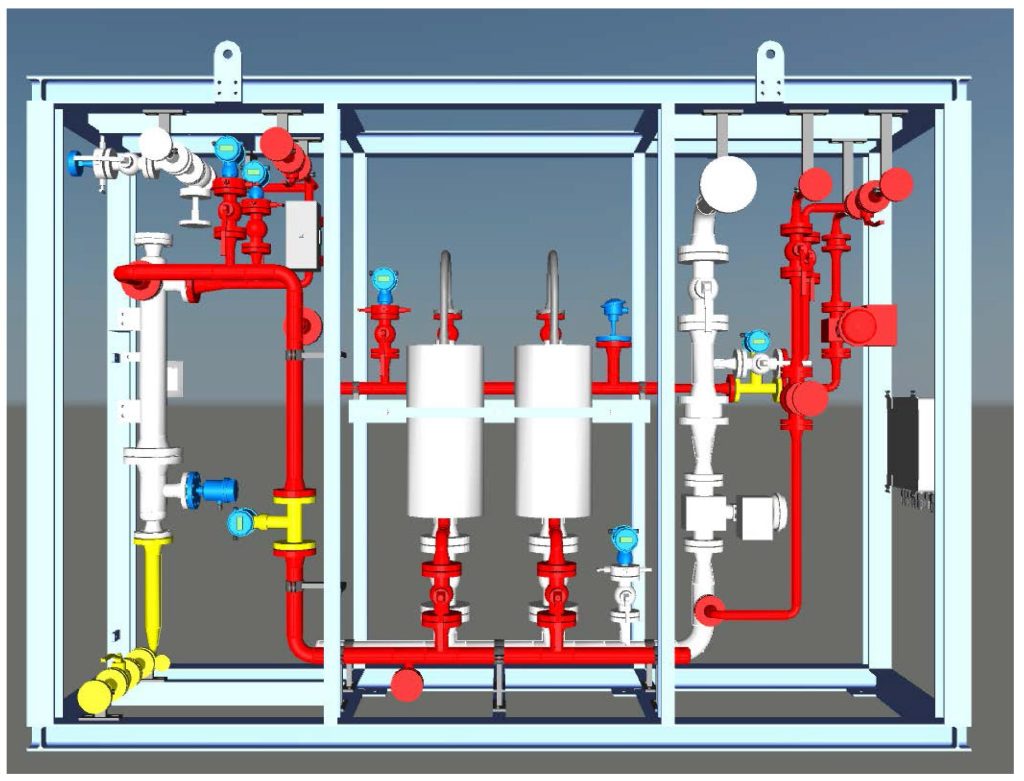

Process Description

The production of Ethylene Oxide (EO) is based on the catalyst-supported, direct oxidation of “pure” Oxygen (O2) with Ethylene (C2H4).

The Ethylene production plant mainly consists of a reactor and a recycle gas loop. The cycle gas is fed back into the EO reactor by the cycle gas compressor.

A small amount of the recycle gas is continuously purged out to prevent the accumulation of inert components like Argon (Ar) and Nitrogen (N2) as well as Ethane (C2H6) in the reaction mixture. These impurities are introduced with the reactants O2 and C2H4.

The purge gas flow contains a significant amount of valuable components especially Ethylene (C2H4), which shall be recovered and recycled for reuse in the process.

By using hydrocarbon-selective membrane, is to separate cycle gas purge stream into an impurities’ rich flow which remains on upstream side and routed to waste heat boiler.

On downstream side Ethylene-rich flow shall be recycled to reactor loop through available residual gas compressor.

This technology as lots of following beneficiary:

- Ethylene guarantee recovery 88.6% which produce more than 1000Ton/Year

- Without power consumption and side services

- 10 years operation without any maintenance